The Science of Window Manufacturing

In the world of window manufacturing, understanding the intricacies of glass production and cutting is essential for delivering high-quality products that meet both aesthetic and functional demands. In this article, we explore the fascinating science of window manufacturing, offering window dealers valuable insights into the process.

Glass Manufacturing: The Center of Window Panes

Glass, the cornerstone of modern windows, undergoes a meticulous manufacturing process to achieve its clarity, strength, and specific properties. Here’s a detailed look at how glass is made:

- Raw Materials: Glass production begins with raw materials such as silica sand, soda ash, limestone, and various additives like alumina and magnesium oxide. These ingredients are carefully measured and mixed to form a batch.

- Melting: The batch is fed into a furnace heated to temperatures exceeding 1500°C (2732°F). In this molten state, the raw materials fuse together, forming a viscous liquid called “glass.”

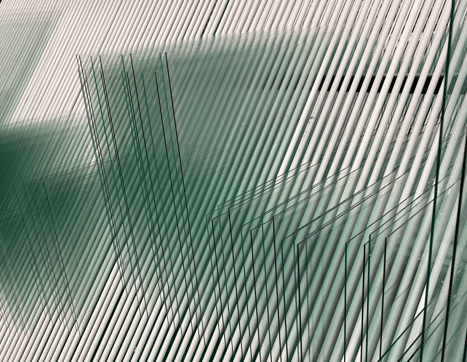

- Float Glass Process: The most common method for producing flat glass used in windows is the float glass process. In this process, molten glass is poured onto a bath of molten tin, where it spreads out evenly to form a continuous ribbon. As the glass cools and solidifies, it undergoes gradual annealing (controlled cooling) to relieve internal stresses and enhance its strength.

- Cutting: Once cooled and solidified, the glass ribbon is cut into large sheets of standard sizes. These sheets are inspected for quality and imperfections before moving on to further processing.

Tempering and Laminating: Enhancing Strength and Safety

To meet the demands of safety and durability in window applications, glass often undergoes additional treatments:

- Tempering: Tempered glass is produced by heating regular glass to a high temperature and then rapidly cooling it. This process creates surface compression and edge tension, making the glass significantly stronger than untreated glass of the same thickness. Tempered glass is essential for windows as it enhances safety by breaking into small, relatively harmless pieces when shattered.

- Laminating: Laminated glass consists of two or more layers of glass bonded together with an interlayer (usually polyvinyl butyral or PVB) under heat and pressure. This process creates a strong, durable sandwich-like structure that retains its integrity even when broken. Laminated glass is crucial for safety and security in windows, as it holds together when shattered, reducing the risk of injury and intrusion.

Cutting and Shaping: Tailoring Glass to Fit Windows

Once the glass sheets are manufactured and treated, they are cut and shaped to fit specific window frames and dimensions:

- Cutting Techniques: Glass cutting traditionally involves scoring the surface of the glass with a diamond or carbide wheel, then applying pressure or thermal shock to induce a controlled break along the score line. Modern advancements have introduced laser cutting for precise and intricate cuts, particularly useful for complex designs or tempered glass.

- Grinding and Polishing: After cutting, the edges of the glass are smoothed and polished to remove any sharp edges or imperfections. This not only enhances the aesthetic appearance but also reduces the risk of injury during handling and installation.

Fitting into Frames: Precision and Sealing

Fitting glass into window frames requires precision to ensure proper installation and optimal performance:

- Sealing: Once the glass is placed into the frame, sealing materials such as sealants or gaskets are applied to create an airtight and watertight seal. Proper sealing is critical for energy efficiency, preventing air leakage, and enhancing insulation properties.

- Insulated Glass Units (IGUs): Many modern windows use insulated glass units, which consist of multiple glass panes separated by a spacer and filled with a gas like argon or krypton. IGUs enhance thermal insulation, reduce condensation, and improve energy efficiency.

Innovations in Glass Technology: Beyond the Window Basics

The field of window glass continues to evolve with technological advancements and innovations:

- Smart Glass: Emerging technologies like electrochromic and thermochromic glass enable windows to dynamically adjust their tint or transparency in response to sunlight and temperature changes, optimizing energy efficiency and occupant comfort. Check out Cardinal’s latest idea here.

- Energy Efficiency: Low-emissivity (Low-E) coatings applied to glass surfaces further improve energy efficiency by reducing heat transfer while allowing visible light to pass through.

- Neat +: An invisible coating applied to the outside of windows, which drastically reduces maintenance. The coating reacts to sunlight and rain, breaking down organic material (waste, dirt, and debris) to leave homeowners with a cleaner and clearer view.

The science behind window glass—from its manufacturing and treatment to cutting and installation—encompasses a blend of precision engineering, materials science, and innovative technologies. For window dealers, understanding these processes is crucial for offering informed recommendations and ensuring the delivery of high-performance windows that meet the diverse needs of their customers.

By appreciating the complexities of glass production and the critical role it plays in window performance, dealers can effectively convey the value of their products to homeowners. Whether it’s enhancing safety with tempered or laminated glass, improving energy efficiency with advanced coatings, or embracing smart technologies for dynamic window solutions, the journey from raw materials to the final fitted window pane underscores the craftsmanship and science that define modern window manufacturing.